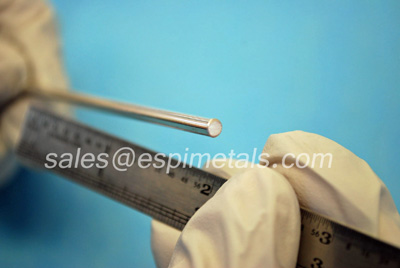

Silver Rod

MATERIAL OVERVIEW

ESPI offers rod made up of many different element’s and/or alloys as well as in numerous other forms and purities; up to 6N (99.9999%) and sells principally to the research and manufacturing communities. Rod often is used as a structural component assumed to possess some mechanical strength without being bundled, whereas wire is usually a single, cylindrical, flexible strand of metal which is used to carry electricity and telecommunications signals or for research purposes. Rod and wire are commonly formed by drawing or extruding which are metal working processes using tensile forces to change its form by either pulling (draw) or pushing (extrude) metal through a die of the desired cross-section to create objects of a fixed cross-sectional profile and both can be made into square, hexagonal, flattened rectangular or other cross-section forms.

Where not specified in the purchase order or contract, ESPI shall apply standard workmanship tolerances. Rounds (rod, wire, etc): +/-10% for diameter and length. Profiles (plate, sheet, foil, etc): +/- 10% for thickness, width and length. Other non-machined solids (powder, shot, pieces, etc): +/-10% for weight, +/-25% for size.

Characteristics: Soft, ductile, lustrous white solid. Highest electrical and thermal conductivity of all metals. Resists oxidation, but tarnishes in air through reaction with atmospheric sulfur compounds. Absorbs oxygen strongly at melting point. Soluble in nitric acid, and alkali cyanide solutions, insoluble in water and alkalies. Noncombustible, except as powder.

Hazards: Tolerance (metal) 0.1 mg/m3 of air; (soluble compounds, (as Ag), 0.1 mg/m3 of air).

In addition to the standard sizes listed in our online catalog custom shapes and sizes for silver rod are available upon request. If you have a custom requirement contact us by telephone at (800)638-2581 or This email address is being protected from spambots. You need JavaScript enabled to view it. for additional diameters, thicknesses or custom sizes.

To view a photo of the item hover over the ![]() icon.

icon.

GENERAL PROPERTIES

|

Symbol: |

Ag |

|

Atomic Number: |

47 |

|

Atomic Weight: |

107.868 |

|

Density: |

10.50 gm/cc |

|

Melting Point: |

961.93 oC |

|

Boiling Point: |

2212 oC |

|

Thermal Conductivity: |

4.29 W/cm/K @ 298.2 K |

|

Electrical Resistivity: |

1.586 microhm-cm @ 20 oC |

|

Electronegativity: |

1.9 Paulings |

|

Specific Heat: |

0.0566 Cal/g/K @ 25 oC |

|

Heat of Vaporization: |

60.7 K-Cal/gm atom at 2212 oC |

|

Heat of Fusion: |

2.70 Cal/gm mole

|

TYPICAL ANALYSES - Impurities in ppm

|

Material / Purity: |

3N5 |

4N |

5N |

6N |

| Ca | 200 | 40 | - | - |

| Na | <20 | <4 | - | - |

| Pb | <20 | <4 | - | <.20 |

| Si | 75 | 15 | - | - |

| Ni | - | - | - | .10 |

| Fe | 40 | 8 | 2 | <.14 |

| Mg | 50 | 10 | - | - |

| Bi | <20 | <5 | <.2 | - |

| Cu | 45 | 8 | .6 | .19 |

| Pd | - | - | .6 | .46 |

SILVER ROD

- Rod is cut to order and sold by the inch or foot. Call or This email address is being protected from spambots. You need JavaScript enabled to view it. for additional diameters or custom sizes.

CUSTOMERS FOR SILVER ROD HAVE ALSO SHOWN INTEREST IN:

SILVER WIRE

SILVER FOIL

SILVER SHEET

SILVER SPUTTERING TARGETS

SILVER POWDER, SHOT, PELLETS, & INGOT

SILVER COMPOUNDS

|

|

ALLOYS

ALLOYS